QUALITY: AN INNATE COMMITMENT

The proven success of the Rodman Group is based largely on its human Capital highly qualified and specialist staff. This fact, added to the ongoing incorporation of state-of-the-art technology, guarantees better production processes.

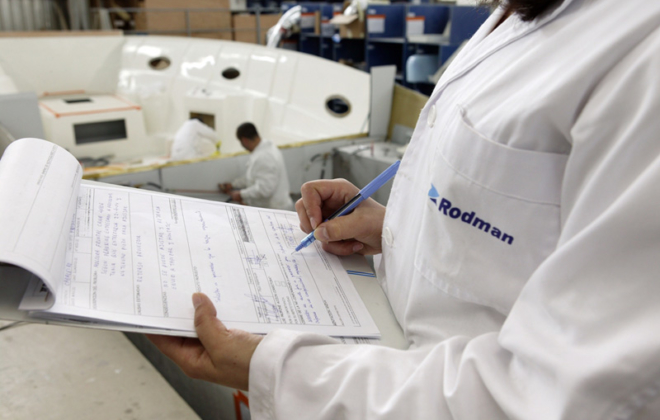

Its spirit of ongoing improvement has led to the Rodman Group developing its own internal quality system: the Rodman Quality System (RQS). This system focuses on exhaustive control of production materials and processes and rigorous open-sea tests for each unit. This ensures the highest quality on delivery of the vessel and guarantees conditions that are unbeaten in the marketplace.

All the Rodman products are backed by the most important international quality certificates: ISO 9001, ISO 14001 and Pecal 2110/AQAP.

All this ensures the highest quality in delivery and warrants conditions that are unequalled in the market.

All Rodman leisure boats offer a commercial limited warranty of 10 years for structural damage and 5 years for osmosis.

SUSTAINABILITY AND ENVIRONMENTAL FRIENDLINESS

The present model of global growth is jeopardizing the physical limits of the planet. The exhaustion of the natural resources, the increase in energy demand and the changes in the chemical composition of the atmosphere are causing great imbalances in the environment, threatening the development of future generations.

Rodman is a company committed to the environment and the future, seeking to set sustainable practices and processes to help reducing waste generation and environmental pollution.

In this context, both the incorporation of processes reducing the massive consumption of raw materials and non-renewable energies and the development of new technologies that promote the efficient management of resources, the use of clean energy and the reduction of CO2 emissions into atmosphere seem quite necessary.

Rodman, since its origins in 1974, has always been committed to its natural environment, basing its business model on finding technological and innovative solutions for the manufacture of its products and contribute to sustainable development, being respectful and caring for the environment, searching for alternative production processes to enable manufacturing by making the best use of the natural resources and diminishing its impact.

In 1999, Rodman established its policy on environmental and energy saving aspects, being one of the leading companies in Spain within its sector of activity. In 2000, Rodman implemented its Environmental Management System according to the ISO 14001 international standard.

In the year 2007, the company took a step forward in its commitment and set itself the goal of obtaining the “Integrated Environmental Authorization (IEA)” with the purpose of protecting the environment as a whole, applying the principles of prevention and applying the principles of environmental prevention and control in an integrated manner. It is then, in 2008 when the Authority concerned provided us with this authorization which among other measures requires us to implement good practices and monitoring and control plans for the management of air, water, noise, waste, soil, atmosphere, etc. in connection with the legislation in effect.

Regarding volatile organic compounds (VOC) emissions, Rodman reduced by 50% its total emissions from 2005 to 2019, and we keep on working on this.

Advanced Composites By Rodman

SINCE 1974 WORKING WITH COMPOSITE MATERIALS

Since 1974, we are working on the development and construction of composite materials products. 50 years of experience and know-how accumulated Rodman placed in a position of leadership in the composites industry.

Our background has always gone hand in hand for the development and implementation of new materials and technology, which have been incorporated into our manufacturing processes.

Advanced Composites by Rodman gives you the ability to design, develop and manufacture any industrial component in composite materials, providing innovative solutions and establishing long-term, based on mutual trust and the needs of our customer relationships.

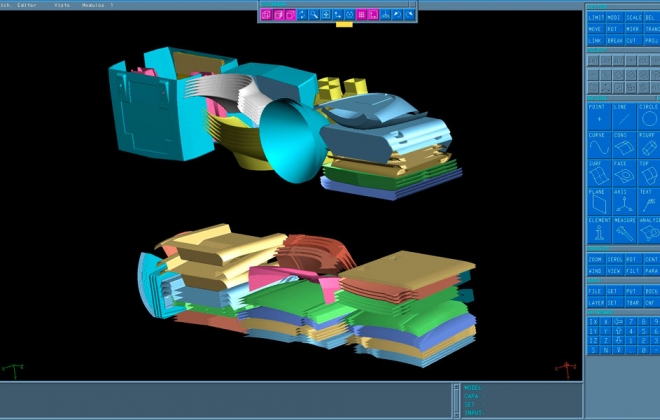

Today Advanced Composites By Rodman designs and produces models and molds for Rodman, and other companies in the shipbuilding sector, which do not have these capabilities internally.

INNOVATION, TECHNOLOGY AND KNOW HOW, MAIN DIFFERENTIAL ATTRIBUTES

Innovation and Technology, plus the know-how and experience of our team, become our main competitive advantage.

At Rodman, we have always been involved in the implementation of new processes, use of new materials and technology.

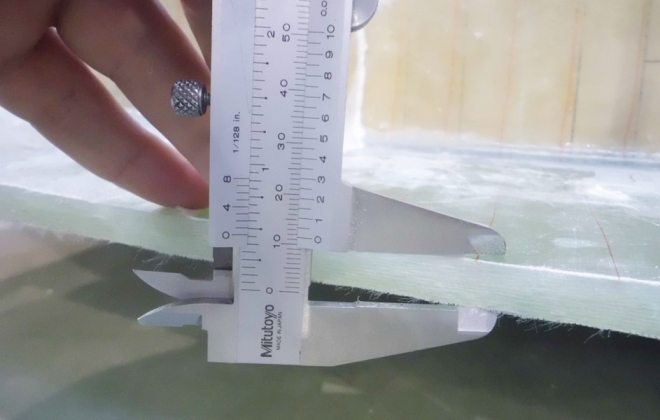

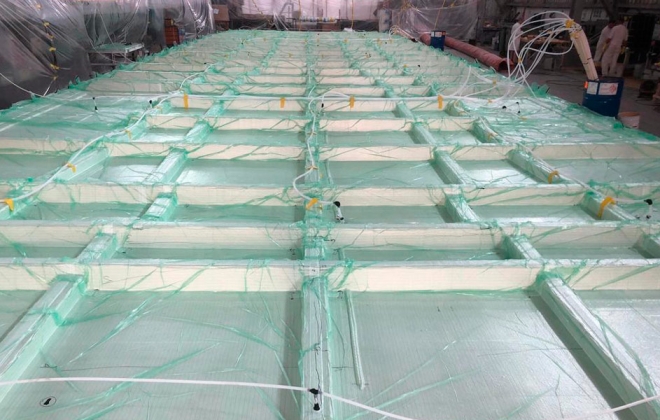

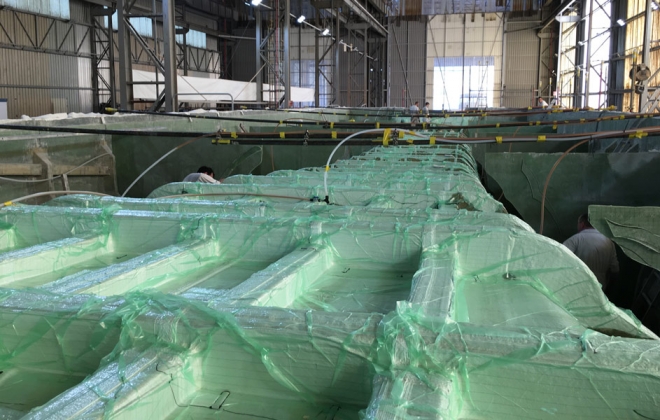

At the beginning of the year 2000, the use of vacuum infusion techniques began to be developed in the shipbuilding industry, for the lamination of hulls and other pieces in Fiberglass Reinforced Polyester. Rodman has been a pioneer in implementing these techniques into its manufacturing processes.

In 2003, Rodman carried out its first experience in laminating a hull of a Rodman 870, using infusion lamination techniques. Since then, the shipyard has continued to investigate the implementation of this process for the building of its boats. Due to the complexity and ease of failure, this manufacturing process must be seen as a trial and error process. In the first experiences each approach must be carefully documented in order to learn from each one of them. Starting with small parts before working with larger and more complex projects.

Since 2010, large pieces, hull, decks and superstructures have been laminated in Rodman to which reinforcements have gradually been added. Increasingly complex pieces have been obtained for many of its most emblematic boats from all its ranges, both leisure and professional range: high speed patrol boats, work boats and passenger catamarans up to 35 m in length.

In the year 2020, the decks of 40 and 42 meter patrol vessels have been manufactured by infusion, including 100% of the reinforcement of both pieces. With these projects, Rodman is consolidating its position as a leader in the implementation of these techniques in large pieces.

The empirical research work carried out during these years in the implementation of these techniques has undoubtedly allowed Rodman to acquire exhaustive knowledge in the improvement of processes and in the adaptation of all the necessary variables to achieve the best results. An added value in the vessels built by Rodman.